Cold Work Tool Steel

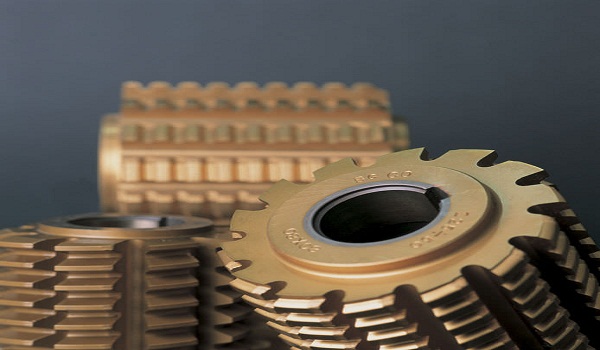

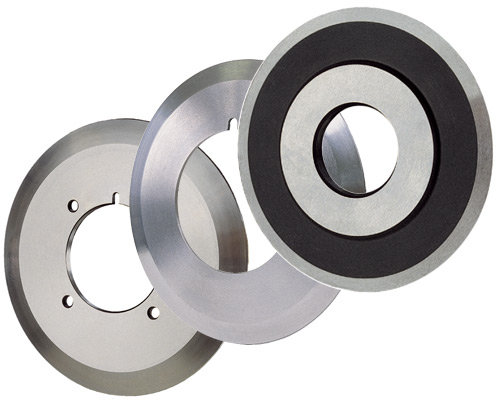

All applications include high mechanical forces and sliding contact between the tool surface and the work material. There are high demands on tool hardness to give wear resistance and resistance to plastic deformation. In order to improve the wear resistance further some of the cold work steel grades are highly alloyed giving hard particles (carbides) in the matrix. The combination of high hardness and hard carbides is however also impairing the machinability.