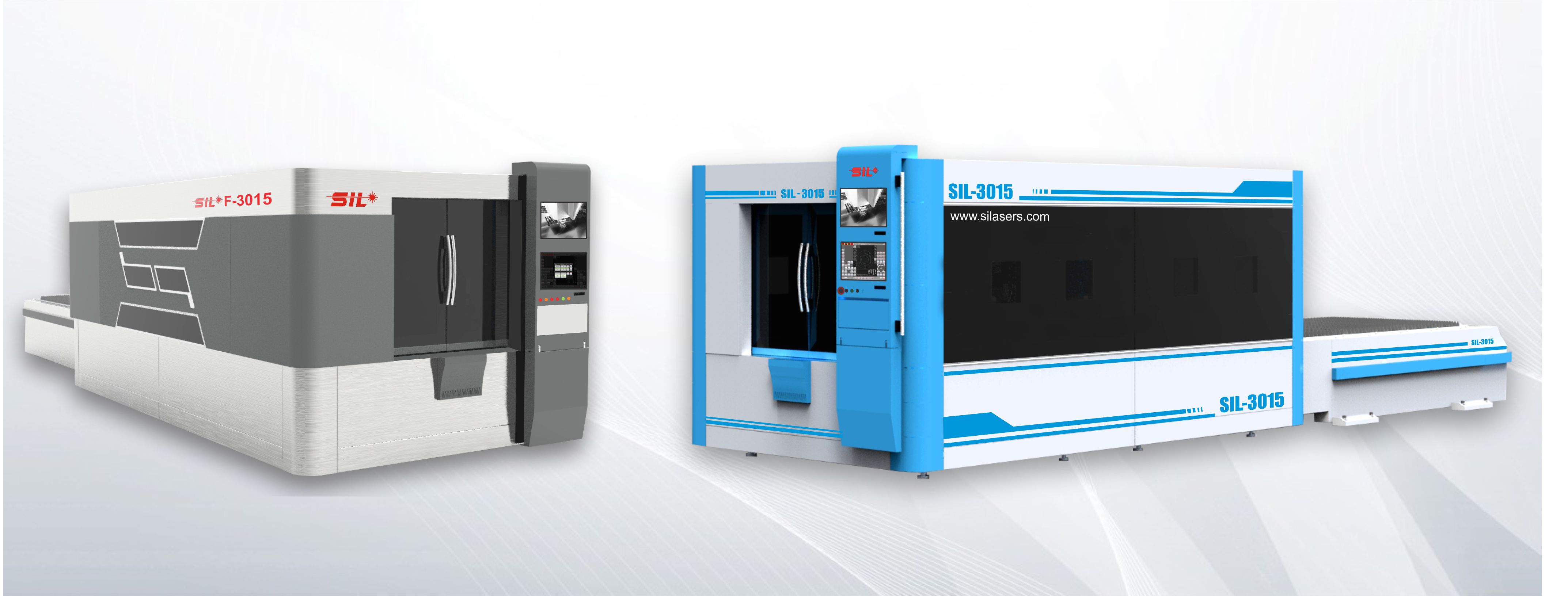

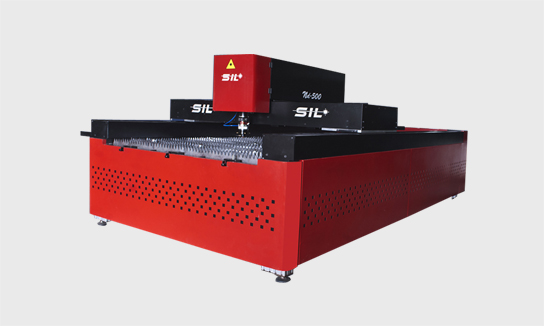

Laser Engraving And Cutting Machine

Applicable Industries:

Signage, Indoor & Outdoor Advertisements, Gifts, Shoes, Toys, Garments, Model cutting, Interior & Decorators, Paper & Packaging, Wood & MDF Cutting Industry, etc

System Features:

- SIL series 1225 large format non-metal laser cutting system

- Special optics for harsh working environments

- High quality industrial chiller, with easy maintenance

- Gantry type structure, high precision imported ball screw system

- Hiwin linear guide rail with stable and high precision transmission

- Light & solid beam structure with superior dynamic performance, modular design

- Offers customized service & economical cutting

- Fixed optical path system ensures consistency of cutting

- Servo motor and drive system technology

- 130 watt DC C02 laser glass tube with 10 months guarantee (150 / 180 Watt laser tube optional)

- Fixed steel strips (honeycomb available on demand)

- DSP based controller for offline work with 32 mb file space

- Red beam pointer

- Twin zone exhaust system

- Engineered for lowest space consumption

- Manufactured in India