Ultrasonic Plastic Welding

REDEFINING THE LIMITS OF WELDING

It is hard to imagine how the requirement for quality and reliability of welds, economy and the ecological demand placed on today is production methods could be met without the modern production engineering of ultrasonic welding.

As a joining process for industrial thermoplastics, the ultrasonic method is very well proven in practise. Particularly in the production of mass- produced parts, the process offers definite advantage over previous methods.

Roop Telsonic Ultrasonix Limited offers wide selection of welding equipment and installation which with respect to generator performance, range of welding force, frequency of operation and possible uses, efficiently satisfies your specific application requirements.

- LINEAR WELDING SYSTEM

- SPIN WELDING SYSTEM.

- HANDY STAR.

- APPLICATION AREAS.

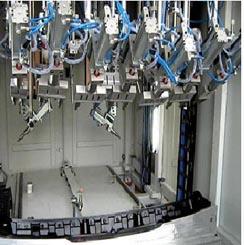

- CUSTOMIZED WELDING PROJECT.

- WORKING PRINCIPLE OF ULTRASONIC WELDING.