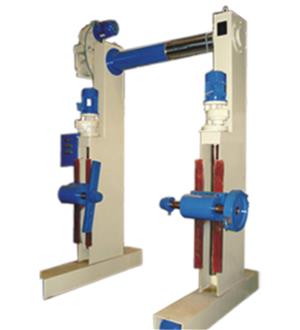

Extruder

Oswal Engineering Corporation supplies the Single Screw Extruders. The Screw and Barrel are most important elements of the Extruder. The Barrel is made of special alloy steel and is honed and nitrided. The Screw is made up of EN material and nitride and hard chrome plated. The machine comes with a hopper dryer and loader. The Screw is combined with the barrel having a properly equilibrated geometry. Extruder control is through Modular Automation system which is assembled in line and allows the customer to synchronize it with the complete line.

Advantage :

- Robust construction and heavy frame.

- Higher output.

- Good melt homogeneity.

- Low power consumption.

- Simple Panels for effective and efficient usage.

- Standard parts for easy replacement.

- Branded drives and motors used for faster service.

- Can be customized.

- Minimum vibration and sound is produced.

- Internationally acclaimed and best quality.

- Simple design for effective troubleshooting and maintenance.

- Helical gear box.