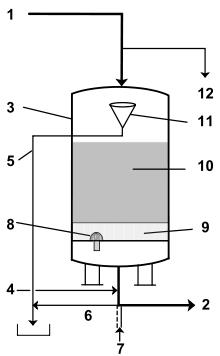

Pressure Sand Filter

The filteration material (sand and gravel) is used to remove the solids from the effluent. For achieving turbidity <10 NTU, this solution is used.

The back wash process is automatic depending on the pressure developed in the filter, which normally happens when the filter is choked with suspended solids.