Products & Services

Bi Vane Inlet Distributor

This is generally used as a low momentum inlet device The inlet stream entering through the inlet nozzle is smoothly divided into 2 equal streams each of which is deflected through 90 to create a centrifugal gas / lquid separation effect. The streams then impinge against the vessel valls and enter the bulk fluid phases to absorb the momentum.

Cyclone Inlet Defoamer

The inlet stream entering through the inlet nozzle is introduced tangentially into a vertical cyclone tube to create a centrifugal gas/ liquid separation effect. The Liquid stream impinges against the cyclone wall and falls, entering the bulk fluid phase via a cross baffle to absorb the momentum. Gas exits the cyclone via a top exit.

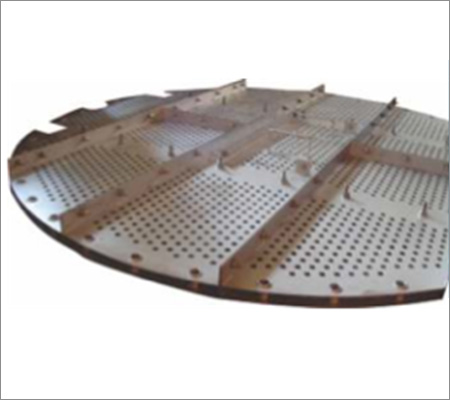

Perforated Baffle Plates

After the inlet device, the liquid passes through distribution baffles which may be single or a matched pair of transverse perforated baffle plates in the liquid zone. Their primary function is to provided a barrier and distribute the liquid evenly from the turbulent inlet zone to the calm separation zone.

Single Perforated Baffle

Description / Specification of Single Perforated Baffle

We are involved in offering a wide range of Single Perforated Baffle to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Single Perforated Baffle. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Liquid Liquid Coalescers

Majority of separators in the oil and gas industry work on the principle of gravity separation. Coalescers are devices which maximise liquid- liquid separation by reducing the effective distance that the dispersed phase droplets need to travel before encountering a coalescing surface.

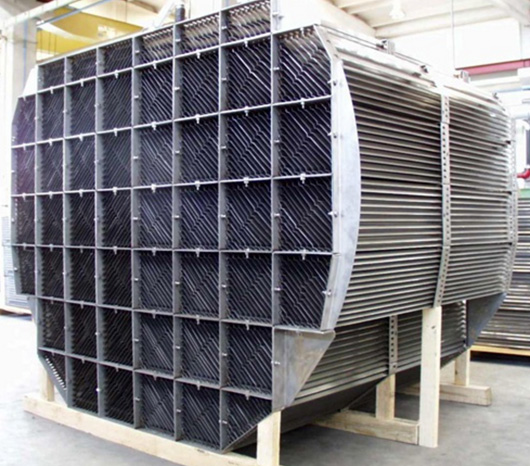

Plate Packs

Gravity separation of oil and water is accomplished by droplets settling. A certain amount of retention time is necessary to allow a droplet to settle and be united to its bulk phase. Plate pack coalescers are used in the liquid section of a separator or scrubber to optimise the degree of liquid-liquid separation. These coalescers provide excellent performance specially in applications where there is a tendency for fouling.

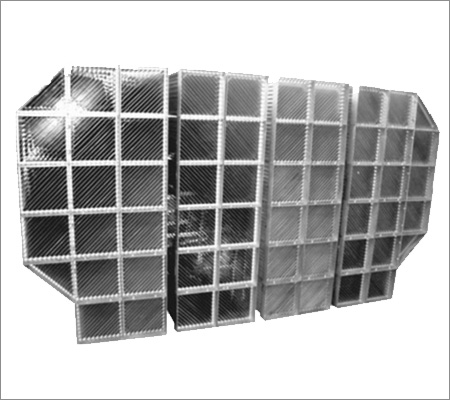

Matrix Packs

The packing is manufactured in corrugated sheets making it strong and well suited for this application. Liquid droplets directly impinge on the irregular surface allowing coalescence to take place. The larger droplets then flow either up or down through the packing and separate out into their respective phase.

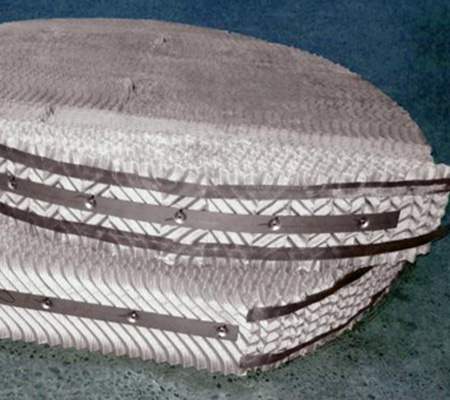

Dual Media Mesh

The coalescer is manufactured from either co-knit metal / plastic filament weave or combining layers of different mesh properties. Liquid droplets directly impinge on the fine wire surfaces allowing coalescence to take place it is usually used in cleaning service for polishing applications.

Mist Eliminators

Finepac offers a complete range of mist elimination devices including mesh pad demisters ,vane type mist eliminators (Chevron equivalent) and liquid coalescers for separation of entrained liquids. Products are available in a variety of metals, plastics and thermoplastics for a wide range of applications

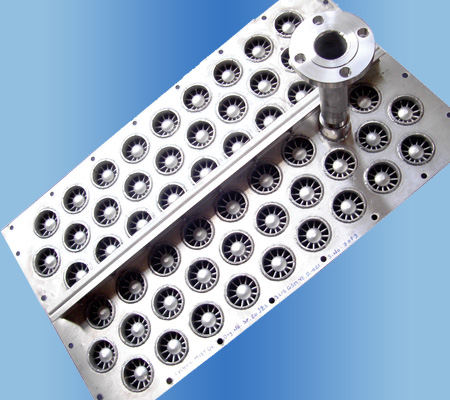

High Speed Axial Cyclones

The high speed axial cyclones [specialist design by Kirk Process Solutions] provides a high degree of separation of fine droplets and dust even at high operating pressures. Due to its high capacity it is ideal for retrofitting in to existing separators when high throughputs are required with improved efficiency.