JOGINDRA ENGINEERING WORKS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to JOGINDRA ENGINEERING WORKS P.LTD.

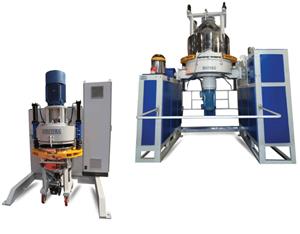

Heating Cooling Mixer Horizontal

Description

Jogindra Heating Cooling Mixer - Horizontal is a combination of High Speed Mixer and Cooling Mixer in Horizontal construction.

The materials in High Speed Mixer is heated by utilization of frictional heat and subsequently the heated compound is transfered to Horizontal Cooling Mixer which cool the material faster by special cooling blade combination of radial and axial design, allowing an increase in the number of batches per hour. The cooling water consumption is reduced, maintainance costs are also lesser. This horizontal construction Cooling Mixer can be fitted to any type of mixer in accordance with customer's requirements.

High Speed Mixer

Description

Cooling Mixer Vertical

Jogindra Vertical Cooling Mixer Vertical is suitable for quick cooling of directly transferred Rigid/ Plasticized PVC Blends from High Speed Mixer. The special designed cooling bladesare a result of faster cooling. A cooling coil is provided at the center portion of the vessel for faster and efficient cooling of compound.

Container Mixer

Description

Ideal for mixing of powdery/grained materials for dispersing, moistening, coating and hot mixing.

- Pigments

- Master Batches

- Powder coating

- PVC , PE, and PP compounds etc.

- Container Trolley

- Water Cooled Mixing/Dispersion Tool

- Frequency Invertor for continuous notational speed

- Nitorgen Injection

- PLC Program Control

- Automatic Feeding Station

- Exhaust System

Batch Conveying Systems

Description

Jogindra offers complete PLC Batching Plants including Storage Conveying, Weighing, Mixing, etc. for continuous Processing in the Mixer. In this system, the PVC and other materials can directly be transferred from bulk cylo or jumbo bag station to weighing hopper for conveying to feeding hopper fixed on top of High Speed Mixer.

Use of this system is recommended in case of continuous compounding for small to medium volume production, thereby minimizing production coasts. The preweighed material is fed into a bag emptying station and is conveyed by a roots blower via rotary airlock and pipeline to feeding hopper (fixed at top of High Speed Mixer) ready for next batch. PLC can be supplied on request.

Single Shaft Shredder

Jogindra is one of the leading manufacturers of high quality recycling units for over twenty years.Our machines are capable of providing high quality output with low running cost.Jogindra is specialized in the production of various units such as single shaft shredders, four shaft shredders, pulverizer, scrap granulator etc. with the purpose of recycling, size and volume reduction.

Our Single Shaft Shredder are suitable for processing various kinds of materials and wastes:

- Light metals scrap (ferrous and non-ferrous)

- MSW (Municipal solid Waste)

- Industrial and hospital waste

- Plastic materials (PET,HDPE, film Big-bags in PP and similar, etc.)

- W.E.E.E. (Electronic and electric domestic waste)

- Plastic and metal tanks

- Electric and high tension cables

- Textiles, Paper, Wood.

Scrap Granulators

Description

Breaker Grinder

|

Pulverizer

|

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.