JANAKSONS OVERSEAS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to JANAKSONS OVERSEAS

Water Treatment Plants

Raw water available also needs to be also treated before it can be put to any use be it for industrial purpose or for civil use. Depending on the source of water such as river, bore well, lake, sea etc. the mode of treatment differs.

Chemical physical: With the help of chemicals, unwanted substances are removed. Chemicals are dosed to allow settling of substances and then the water is passed through the clarifier.

Ion Exchange: the exchange of ions of the same charge between an insoluble solid and a solution in contact with it, used in water-softening and other purification and separation processes. Various ion exchange processes are there such as softening, decarbonisation, demineralization etc

Filteration: In fresh water filteration is usually done by Sand or activated carbon.

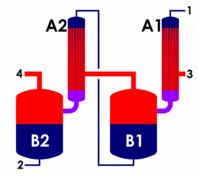

Reverse Osmosis: If the fresh water contains some parts of dissolved solids then a small RO plant is proposed to remove the TDS in water making it usable for the industry.

Desalination: Water having very high levels of TDS such as available in the Sea beds then a BIG Reverse Osmosis plants is used. We offer DESAL plants 1) containerised and 2) complete solutions for treating large volumes for providing cities with drinking water.

Mobile Drinking Water Plants

Mobile primary water treatment units are designed to satisfy all the drinking water production needs in zones where the only one water source is available such as a river, well or lake. They are designed for producing drinking water according to many different demands and consumption requirements.

The units are mounted, according to their size, on rubber in carts, pick-ups or in shelters and are designed to be easily towed and completely self managed thanks to their internal generator. They can be supplied with a water storage tank or with a bag-packing system. Mainly used in areas which are effected with droughts, refugee camps, villages, military missions.

- RIVER WATER TREATMENT

- LAKE WATER TREATMENT

- SEA WATER (DESALINATION)

- DRINKING WATER

Water Management Plants

The solutions offered for wastewater depends on parameters such as the feed, COD, BOD, TSS, Colour, TDS etc and these parameters vary. Our design team has many years of experience in handling and treating BIOLOGICALLY the effluent generated from Textile, Tannery, Sewage, etc.

SCREENING

As the word suggests, this process is to screen the water from the coarse and medium-fine solids being discharged in the wastewater. It helps to avoid settling of this solid in the tanks and clogging of crucial and expensive equipment installed in the plant.

The screen section is placed normally at ground level before feeding the water to the effluent treatment plant. The screening equipment can operate both automatically or manually.

Types of screens: Rotary Drum, Brush Screen, Disc Screen, etc.

EQUALISATION

The equalization or homogenization process forms a very important part of the complete scheme of the ETP. The process house normally discharges different qualities of water with different flows. Hence it is important to mix the water well to ensure that an average quality of effluent is fed to the oxidation plant.

The mixing of water is done with the help of diffusers where the tanks are constructed in rectangular shape or ejector pumps and flow makers where the tanks are in carousel shape. Very minimum air is also fed into the equalization to provide some oxygen to the bacteria and avoid foul smell.

After this process, the water is neutralized in a separate tank with sulphuric acid or soda depending on the level of pH.

AERATION

It is the “heart“ of the plant.

The Aeration Tank is where all transforming phenomena of pollution contained in the wastewater takes place, thanks to bacteria and microorganisms. Bacteria, in the course of their life, grow and multiply themselves. This is possible through two processes: the energetic and the synthesis.

Depending on the size of the tank to be constructed we design both rectangular shape and carousel shape tanks.

It is in the process that the COD, BOD, TSS, surfactants are reduced.

DIFFUSERS / OXYGEN SUPPLY

Fine bubble diffusers are installed in the bottom of the tank. The quantity of air supplied is automatically controlled by a dissolved oxygen-meter, which is positioned inside the aeration tank. It drives the blowers permitting to furnish the exact quantity of oxygen required by adjusting the airflow of blowers.

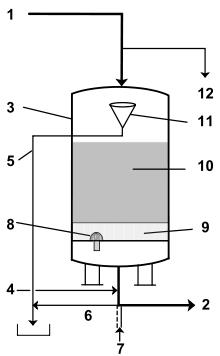

Pressure Sand Filter

The filteration material (sand and gravel) is used to remove the solids from the effluent. For achieving turbidity <10 NTU, this solution is used.

The back wash process is automatic depending on the pressure developed in the filter, which normally happens when the filter is choked with suspended solids.

Disc Filteration

The Disc Filter is a high-rate filtration device that utilizes an innovative woven polyester pleated filter panel design. The Disc Filter inside out filtration design allows the water to flow into the center drum and then out through the disc filters capturing solids on the inside surface of the media. This filtration characteristic eliminates the need for a separate system for handling floating material and settling sludge. The captured solids are also backwashed into a reject trough using a one-pass spray cleaning system. A backwash cycle is automatically initiated by a level probe in the influent channel with filtration continuing during backwash.

For achieving turbidity levels less than <5 NTU this solution is used.

Ultra Filteration

Treatment through Ultra Filtration is a technology for suspended solids separation, according to membrane weight and their molecular cut. Applying different pressures allows the membrane to act as a sieve. The substances smaller than the diameter of the pores of membrane pass the membranes as permeate while the bigger ones are kept as concentrate. During the production, it does not require chemical reagents dosages and power consumption is limited. The backwash of

For achieving turbidity levels less than <1 NTU this solution is used.

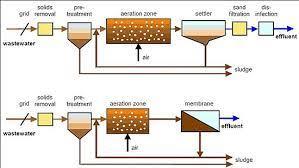

Membrane Bio Reactor

MBR is the latest technology in the world for filteration and with its use many filteration process are eliminated such as clarifier, sand or disc filtration, ultra filteration.

This is a membrane based filtration system where the membranes are put in the same liquor of the biological/ oxidation tank. MBRs are used to achieve filtration levels of <1 NTU turbidity. Depending on the application and type of wastewater we design noodle type membrane modules or flat plate type membrane modules

They occupy less space and work at very minimum running cost.

Circular Knitting Machine

With the philosophy to serve clients by producing the best, Keumyong Machinery Co. was established in the year 1956. Since then Keumyong have devoted to manufacture various quality circular knitting machines and important components of diesel engines. With the state-of-the-art computerized facilities, advance technology and a long history of quality workmanship and production techniques, no wonder Keumyong has come out with many innovations and has maintained excellence in their products.

ADVANTAGES

- Less load by high precision

Perfect gaps between all parts resulting In

- Smooth passing of Needles between cylinder and cams

- No vibration of needles

- better quality of plated fabric

Less friction for each part

- Longer needle’s life

- Save power consumption

- Fantastic Machine Speed

The speed factor of the M/c is designed to 1500.

SF (speed factor) = Diameter X RPM

SF 1500 = 30” X 50 RPM

- Awesome Specification of Rib

Keumyong have different types of Rib machines like 2 feeders/Inch, 2.4 feeders/Inch, 2.8 feeders/Inch & Interlock machines like 3.2 feeders/Inch, 3.6 feeders/Inch.

- Immediate restart after Setting

(1) User’s friendly design has no need to stop machine for long time. Cylinder conversion is very easy as the dial alone needs to be adjusted without adjusting the Cylinder.

(2) Mono cam structure as such no need to change the Knit cams for Rib fabric & Interlock fabric while conversion

- Save Maintenance Cost

1) Life time guaranty of Ceramic yarn carrier - Other’s need the replacement for every 3-4 years.

2) Longer needle life by Ceramic yarn guide and high precision in pass way of needle.

3) Special servomotor for take-up system – no need of replacing carbon brush.

4) Double Knit machines have special oil pump for lubricating the top counter

INNOVATIONS BY KEUMYONG

| DESCRIPTION | YEAR |

| Mini Jacquard | 1990. 7 |

| Computerized 4 Color Auto Striper | 1995.10 |

| 3 Position Computerized Jacquard | 1995. 8 |

| Auto Doffer System | 1994. 3 |

| Computerized Double Jacquard | 1988.10 |

| Computerized Pile Loop Jacquard | 1995.12 |

| Computerized Rib-Mesh Jacquard | 1989. 8 |

| Computerized Single Jacquard | 1987. 5 |

| High Pile Jacquard | 1998.12 |

| High Speed Plush Knitting Machine | 1987. 5 |

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.