HYDEN PACKAGING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HYDEN PACKAGING P.LTD.

Uni Directional Inspection Machine

A versatile machine based on modern technology capable of high-speed slitting and rewinding. This machine can be fitted with an inspection camera of your choice that will be integrated to give it defect detection capability. Defective labels that are captured by the inspection camera will be positioned precisely on the splice table for the operator to remove/replace.

As a stand-alone slitter/rewinder this machine notches a speed of 300 meters per minute and offers very high speed conversion. Easy and fast set-up and easy operation assures productivity. A wide range of substrates can be inspected/slit including paper, plastics films, Aluminum foil and the machine offers excellent quality in terms of slitting as well as flawless winding.

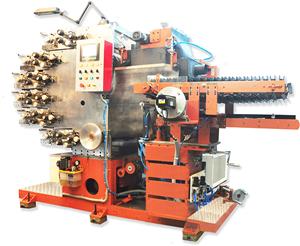

4 Color Lowspeed Dry Offset Presses

The Hyden 4080 MiniPrinter is a compact low speed four color Dry Offset press. Specially designed for printing on Injection molded and Thermoformed plastics disposable containers, used in food and beverage packaging, this machine has all the features and build quality of our standard range of printers at a low equipment cost. The 4080 MiniPrinter has been particularly manufactured for low printing volumes and small batch sizes.

The 4080 MiniPrinter is a fully automatic 4 color press that gives excellent print quality while maintaining tight color register. It uses solvent based inks and is equipped with a heat drying conveyor for curing printed containers. A re-stacking system allows easy and convenient operation. The press has a small and compact footprint requiring a low operating area and is extremely easy to install and set-up.

The 4080 MiniPrinter is manufactured by precise machining techniques and workmanship and has a solid build. The TESLA Series 408 Control System is simple and easy to maintain and is made user serviceable and therefore does not require any specialised maintenance. Comprehensive instructions and maintenance manuals are provided with the equipment to assist set-up and maintenance.

The 4080 MiniPrinter gives an excellent print reproduction with consistent results. This is becaiuse it has been manufactured with the same Care, Dedication and Precision that goes into the build of our most advanced presses. No compromises are made in the materials or workmanship that go into the build. This make the equipment worthy of a long service life at a low maintenance cost. When installed on your shop floor you will join a large base of satisfied customers, because Customer Satisfaction is what all of us at Hyden really care about.

4080 Miniprinter

The Hyden 4080 MiniPrinter is a compact low speed four color Dry Offset press. Specially designed for printing on Injection molded and Thermoformed plastics disposable containers, used in food and beverage packaging, this machine has all the features and build quality of our standard range of printers at a low equipment cost. The 4080 MiniPrinter has been particularly manufactured for low printing volumes and small batch sizes.

The 4080 MiniPrinter is a fully automatic 4 color press that gives excellent print quality while maintaining tight color register. It uses solvent based inks and is equipped with a heat drying conveyor for curing printed containers. A re-stacking system allows easy and convenient operation. The press has a small and compact footprint requiring a low operating area and is extremely easy to install and set-up.

6 Color High Speed Dry Offset Presses

The M-6250M Dry Offset press has been designed to deliver vivid 6 color decoration on disposable containers manufactured from HIPS or PP. This press gives sharp and vivid print reproduction and comfortably prints vignettes and half-tones.

Dual form rollers and electronic ink flow adjustments along with precise and sturdy craftsmanship ensures attractive decoration on the containers. The UV-OMC system immediately cures printed containers allowing high production rates. Optional features such as automatic re-stacking and Corona attachments are available to enhance the capabilities of the press.

The Signature Series upgrade available for this press provides total automation and includes a stack buffer for automatic stack feeding into the press and a re-stacking system with cup counting and stack segmenting.

A simple to operate and easy to maintain control system manages the press. Built with standard high quality components the control system is completely reliable with respect to press management as well as least maintenance.

The press is equipped with the Series 625 automation manufactured by TESLA Controls and is user-friendly and fully user maintainable. At no point of time will it ever be required to call for a Tesla Engineer for control system maintenance. The very detailed and comprehensive service manual and on call support allows the user to address any system break-down and restart production with least down time. Standard parts from reputed manufacturers and a fast supply of spares ensures this. A control pendent on the press provides operational ease and easy access to basic press controls and ink management. Press management is therefore convenient.

The M-6250M is built for continuous high production runs and will give years of reliable service requiring only simple and basic maintenance. This is because all Hyden presses are manufactured to exacting specifications and component standardisation. The Care, Dedication and Precision that has gone into the build will ensure a dependable performance from this press.

8 Color High Speed Dry Offset Presses

The Hyden M-8350M is the most advanced Dry Offset press offered for the decoration of disposable plastics containers. This press has been designed for offering a vivid decoration on the containers and has features that allow high quality vignettes and half-tones to be printed on disposable containers.

The press features water-cooled rollers to maintain ink viscosity. Dual form rollers deliver ink precisely to the printing plates. Precise adjustment of the form roller and plate cylinder contact pressures makes it possible to set-up the press for fine results. The ink flow can be adjusted precisely through the machine control and the ink ducts are equipped with automatic agitation systems for precise ink delivery.

The print cylinders feature a precision Pin-Bar mounting system that allows for 'First time make-ready' greatly reducing the time required for plate mounting and color registration. This allows complex jobs to be registered and set up quickly. The ink-heads feature automatic wash-up for quick color changes.

Cup to printing blanket pressure is precisely adjustable electronically through a single-axis Servo controlled slide also featuring mandrel position memory for quick engage and disengage with the blanket and automatic return to the set contact position.

A stack buffer with logic controlled stepping drops stacks of un-printed containers into the press. A Servo driven auto-loader with 4 progressive pitch screws separates the stack and feeds the cups onto printing mandrels that are driven and synchronized with the blanket drum. The printing mandrels also rotate at the UV irradiator and mandrel rotation is monitored by the control system that gives an alarm if any of the mandrels do not rotate sufficiently during irradiation. No-cup No-Print and Double-Cup Shut-Down are optional accessories.

The press features a compact UV OMC system that cures printed cups and the irradiator radiation is automatically blocked during UV stand-by. A light-weight quick change turret system reduces the make-ready time for a new product.

After printing and curing the re-stacking unit of the press automatically stacks printed cups of pre-derermined count and ejects them onto a collection tray for packing.

The HYDEN M-8350M press is equipped with the TESLA Controls 8350 ServoCAT control system that manages all the press and auxiliary functions

Individual control has been provided for the print drum, indexing unit and the feeding unit that assists in the make-ready of the press. In operation, all units synchronise and run in precise sync

The PLCs, Motion Controller, HMI and Servo Drives have been equipped for remote diagnostics and software updates and TESLA engineers have the capability of taking over the control system remotely for diagnostics and repairs.

The Hyden M-8350M press is the choice when the printing requirements are critical and spectacular decoration is desired. We understand the need of the packaging industry and have therefore evolved with it.

6 Color Tube Printer

The Hyden 6100T Tube Printer is specially designed to meet the challenging requirements of printing conical Injection Molded plastics tubes and can therefore comfortably also print cylindrical lami-tubes used in cosmetic and pharmaceutical packaging. This press delivers extremely fine printing quality and decorates tubes in up to 6 colors. Incorporating a host of advanced features allows this press to offer superior print quality and ease of set-up and operation. Capable of fully automatic and continuous runs, this press delivers consistently accurate print reproduction.

The Hyden 6100T incorporates anti-backlash gearing, clamp type plate cylinders and ink agitation units. The tube in-feed system is developed in a manner capable of handling conical tubes and offers continuous feeding on to printing mandrels. A no-tube detection system disengages the printing mandrel from the blanket and avoids an on-mandrel impression. An electronically managed ink in-feed system offers precise adjustment of color deposition via the system touch-screen HMI. The Magicure UV-OMC system immediately cures printed tubes and ejects them onto a servo positioned collection conveyor that offers preset counting and stacking of printed tubes. A varnishing head with UV-OMC is also offered as an option.

The press is managed by the TESLA Controls 6100 ServoCAT control system that manages all press functions via a touch-screen HMI. Press operation and ink management as well as diagnostic and fault data is accessed via the HMI. The control system is capable of interfacing with a corona pre-treatment system for operational and safety functions.

The Hyden 6100T is a rugged and spohisticated press that will deliver great results at low operating and maintenance costs. This is owing to the Care, Dedication and Precision that goes into the build of all Hyden presses. We are confident that you too will experience the satisfaction felt by all Hyden customers.

Bi Directional Inspection Machine

The B400HS Label Inspection Slitter-rewinder was launched at the LabelExpo India 2016 show. This machine has been designed for critical inspection requirements, particularly in the Pharmaceutical sector. This machine offers fail-safe inspection of printed label rolls through its Re-inspection Mode. When a defective label is captured by the Inspection camera the machine brings the label to a splice table where the operator confirms the defect and replaces the defective label. When the machine is re-started, the replaced label is re-inspected by the Camera to confirm that it is defect free. This mode of operation offers fail-safe defect detection.

The machine is also capable of on-line slitting and rewinding during inspection and has a top conversion speed of 300 meters per minute. The slitting system is fast to set-up and is precise and offers fine slitting quality for a variety of label stock substrates.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.