HI TECH ELASTOMERS LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HI TECH ELASTOMERS LTD.

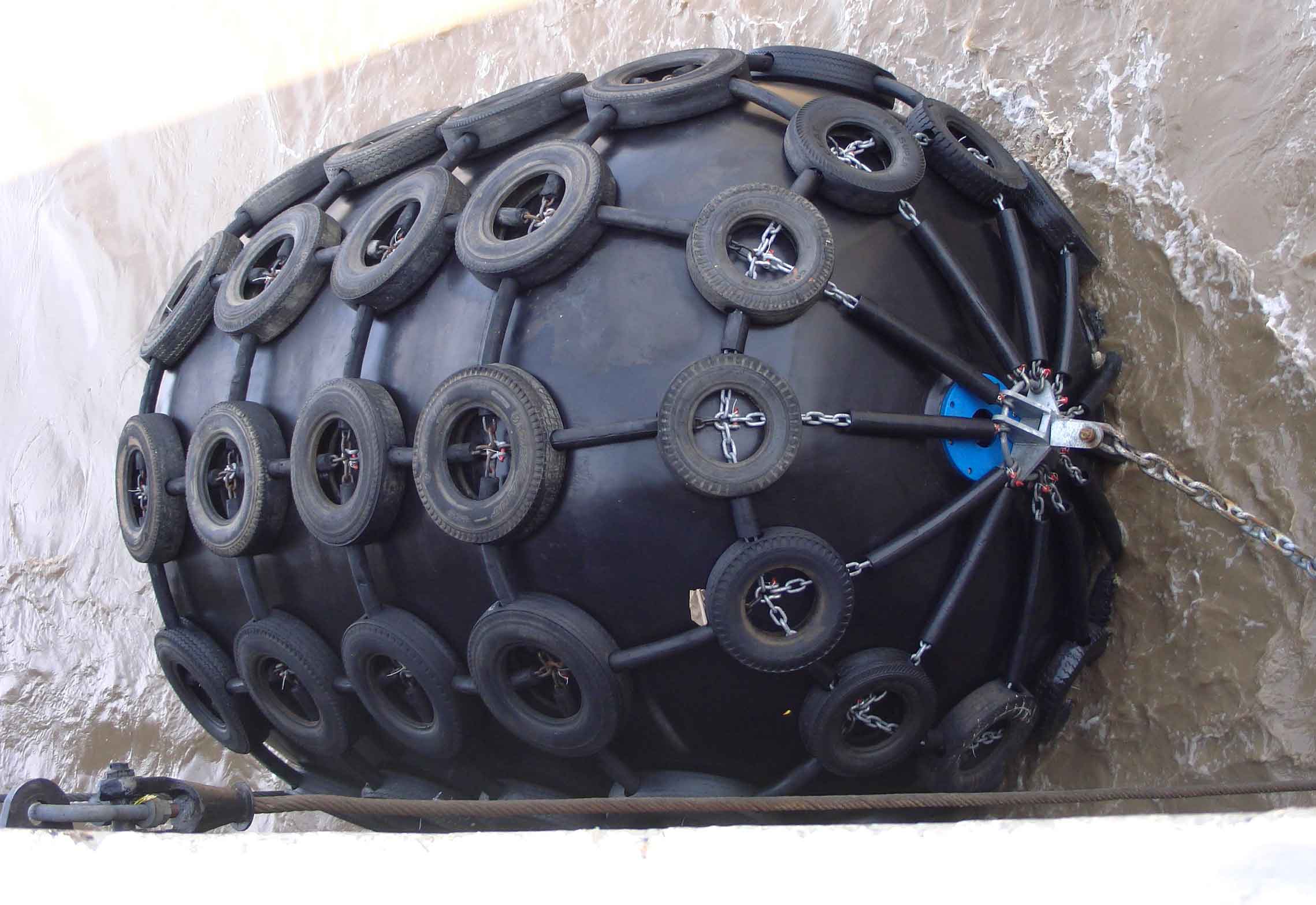

Aircraft Moulded Chain Net

FEATURES:

•Manufactured from Aircraft tyres/Specially moulded tyres.

ADVANTAGES:

•Long service life.

•Low maintenance cost.

APPLICATIONS:

•Used in Ship-to-Ship Transfers

•Used as solution for temporary and/or emergency fendering system installations.

•Used for tankers, gas carriers, bulk cargo ships, fast ferries & other aluminum hull vessels.

Grey Chain Net

FEATURES:

•Special chain net harnessing with non-marking grey/white tyres & grey/white sleeves.

ADVANTAGES:

•HPF-GCN fenders overcome the problem of black marks left on the hulls of navy ships and passenger cruise liners.

•Portable and easy for local berthing.

APPLICATIONS:

•Specially useful for naval ships.

•Use in Ship-to-Ship Transfers.

•Used as solution for temporary and/or emergency fendering system.

Rope Or Fibre And Rubber Net

FEATURES:

•Rope/Fiber/rubber sleeve nets are designed to provide an extra protective layer for the pneumatic fender which increases their shelf-life.

ADVANTAGES:

•Wire rope net is lighter than a chain net.

•Rubber sleeves provide an additional protection against scratching of hull.

•Fiber net has a strong fiber bundle compare to chain & wire rope which provide additional strength.

APPLICATIONS:

Used at terminals where the risk of fire is high viz. LNG Terminals.

Pneumatic Fenders Sling Type Black

FEATURES :

•HPF-SB does not have harnessing and are known as SLING type fenders.

•HPF-SB has thicker skin compared to the fenders with chain-net-tyre harnessing.

ADVANTAGES:

•Being sling type i.e. without chain-net-tyre harnessing; they render easier + faster handling & maintenance.

•They have less susceptibility to puncture as their skin is thicker.

Foam Fenders

FEATURES:

•High energy absorption with relatively low reaction force.

•Thick and tough filament nylon reinforced non-marking urethane skin which makes it durable to extreme marine weather condition.

•Resist UV rays and ozone effect.

ADVANTAGES:

•Low maintenance & cost effective.

•Extremely robust surface.

•Small damage can repaired easily on site.

Donut Fenders

FEATURES:

• High energy absorption with low reaction force.

• Free rotating design gives low shear force.

• Fenders buoyancy allows it to freely float with water level.

ADVANTAGES:

• Flexible design.

• Safe and low maintenance.

APPLICATIONS:

• Lock entrance.

• Corner protection.

• Bridge protection and is used where large tidal changes occurs.

Hi Tech Hydro Pneumatic Fenders

FEATURES:

•Special subset of pneumatic fenders.

•Performance can be adjusted by the air –water ratio.

•Longer than deep draft channel/pontoon and are easier to reposition.

ADVANTAGES:

•Very low hull Pressure.

•Prevent ship’s hull from damage.

•Provide large contact area that distributes the load

APPLICATIONS:

•Used for submarines.

Nova Cone Fenders

FEATURES:

•Highest energy absorption to reaction ratio of any fenders.

•Highly durable and efficient.

•Higher shear stability & inherent resistance against shear forces.

ADVANTAGES:

•More stable at large compression angles.

•No reduction of energy up to 10 degree deflection angle.

•Internal stopper restricts deflection of HNC beyond design parameter.

APPLICATIONS:

•Applicable to all type & size of vessel berthing .

Cell Fenders

FEATURES:

•Simplicity with high performance and strength.

•Strong and well proven design.

•Good shear force resistance.

•High energy absorption to reaction force ratio.

ADVANTAGES:

•Most commonly used fender in port.

•Large mounting flanges distribute load over the back of the fender panel frame.

•Support large Panels.

APPLICATIONS:

•Used for large size vessel.

•Oil and LNG facilities

•Offshore platforms

•Multi-user berths

Z Type Fenders

FEATURES:

•Modular fendering system which provides most cost effective solution.

•Can be engineered with options of conventional steel panel & UHMW-PE panels which are very light weight and maintenance free.

ADVANTAGES:

•Easy installation of the mounting bolts.

APPLICATIONS:

•Fendering system for minimum limited wharf area.

•Ro-Ro jetties.

•Multipurpose Berth.

•Offshore structure applications.

Key Hole Fenders

KEY HOLE FENDERS :

The keyhole fender was designed for heavy duty tug operations. The mounting typically using two metal bars provides a very secure fixture. The face of the keyhole can be made either flat or ridged depending on the amount of friction force the customer wishes to generate between the tug and the other vessel.

Tug Cylindrical Fenders

Hi Tech’s HTCT fenders can accommodate the bow flares on modern ships when acting as the pushing fender on the bow or stern of tugboats. The HTCT comes in various lengths with the dimensions shown in the table. Each individual section is joined to the adjacent section using an internal spigot allowing lengths suitable for any tugboat. They are mounted using a combination of both internal chain and circumferential straps that fit in grooves in the segments.

Tug Square Fenders

FEATURES :

•Square fenders are tough proven design.

•Available with 'D' shape bore & 'C'/'O' shape bore.

•Ideal for tough service environments.

ADVANTAGES :

•Available in various range of sizes to suite every requirement.

•Close fitting reduces risk of ropes or other protrusions being caught between the sections.

Shock Cells

Hi-Tech shock cells (HSC) for offshore platforms was developed as a safe efficient boat landing system that can absorb energy in both deflection and shear. The shock cells can be manufactured with or without an eccentric bumper ring. The basic principle of a shock cell is the adhesion of rubber to two concentric steel tubes.

Bumper Rings

Hi-Tech Elastomers has developed a rubber ring (HBR) which can be used to encase a pile or cylinder component in a barge bumper providing extra energy absorption capability and preserving the integrity of steel cylinder. The ring will also rotate around the cylinder thus minimizing with the shear forces imparted from a vessel with lateral movement during berthing operations.

Shock Pads

Hi-Tech Elastomers has developed shock pads for the off-shore industry based on the bridge bearing pads. These pads are a combination of steel plates with rubber vulcanized between them.Used mainly in lifting systems of self leveling platforms as shock absorbers and vibration dampers, shock pads may be used in other application requiring support of heavy loads without a rigid structure.

Shear Fenders

Hi-Tech Elastomers shear fenders (HSHF) are designed to absorb energy through the stretching of the elastomeric component in the lateral direction while maintaining the ability to support heavy loads perpendicular to that movement. The shear fender also maintain a linear load vs. deflection characteristic throughout their usable range of deflection.

Barger Bumper Assembly

Hi-Tech Elastomers has the ability to package its shock cells with high strength steel barge bumper cylinder providing the customer with complete barge bumper system for installation on their platform.The Hi- Tech engineering department has the ability to design a barge bumper system , analyze it for all loading condition then have the system manufactured in our production line .

Marine Buoys

HI-TECH MARINE BUOYS :

Hi- Tech has bought a technological breakthrough by developing steel- reinforced rubber buoys over the conventional MS, PE,GRP & FRP fabricated buoys.

FEATURES :

•Low weight & Low maintenance

•Flexible & Easy to handle

•Sustaining stable Load

•Provide great buoyancy in deep water

Modular Floating System

HI-TECH MODULAR FLOATING SYSTEM :

It helps to create all kind of floating structures of easy assembly and low cost, including the floating facilities for various customised applications.

One can make floating structure such as mentioned below:

• Floating docks

• Floating platforms

• Jet slide dry docks

• Marinas

• Pontoon bridges

• Floating walkways

• Water parks

• Platforms for floating houses

• Floating work platforms

• Jet ski docks & swimming pools + floating platforms for games

• Fishing farms & nautical clubs

• Platforms for rigid and semi rigid longboats

• Floating ports & piers

• Floating dikes & landing docks

• Floating supports & platforms of marine investigation

Wave Abater System

HI-TECH WAVE ABATER SYSTEM :

•As wind-generated waves enter shallower coastal waters they generally become unstable and break, dissipating a fair amount of their energy. However, the remaining energy in the broken waves still has the capacity to cause shoreline erosion and/or suspend bottom sediment, which degrades water quality.

•Hi-tech’s Wave ABATER system (HWAS) helps extenuate the harsh effects of natural and artificial effects of waves.

•The system is engineered to act as floating breakwater thereby reducing the effect of wave when it hits the system and renders safety to the marina basin.

Protection Barriers

HITECH PROTECTION BARRIERS :

Hi-tech provides various types of marine protection barriers to protect marine assets. Security of marine assets has become necessary in recent times and hence a marine protection barrier is essential security equipment for NAVY ships and other vessels.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.