ENNOVATE DESIGN AND ENGINEERING SOLUTIONS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ENNOVATE DESIGN AND ENGINEERING SOLUTIONS

Reactors Or Reaction Vessels Or Chemical Reactors

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | Upto 50 KL |

| Classification : | Jacketed | Limpet Coiled | Internal Coiled. |

| Reactor Manufactured for : |

API, Bulkdrugs, Ethoxilation, Hydrogention, Oxidation, Distillation, Precipitation, Enzymes, Alkyd Resin, Polymer Emulsion Plant, Homo Polymer , Co-Polymer , Styrene Acrylic resin, All types of resin etc. |

Salient Features

- Design in compliance with international standards – ASME Sec VIII DIV I , DIN, PED

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines

- Extensive analysis and testing of raw materials as per standard

- Energy Efficient agitator design.

- Agitator design to meet product specification to get better yield.

- Better Heat Transfer

- Statically / Dynamically balanced agitator to ensure vibration free operation

- Reduce maintenance & operating cost due to high accuracy in agitator ( maintaining permissible run out , perpendularity, concentricity of agitator ).

Distillation Columns And Packed Columns

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | Upto 1500 mm diameter |

| Classification : | Distillation | Fractionation |

| Distillation Column for : |

API , Bulkdrugs, Ethoxilation, Hydrogention, Oxidation, Distillation, Precipitation, Alkyd Resin, Polymer Emulsion Plant , Homo Polymer , Co-Polymer , Styrene Acrylic Resin, All types of resin etc |

Salient Features

- Design in compliance with international standards – ASME Sec VIII DIV I , DIN, PED

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines.

- Extensive analysis and testing of raw materials as per standard

- Maintaining concentricity for easy insertion and removal of structured packing.

- Minimizing corrosion by providing anti corrosive paint on MS Part.

Heat Exchangers Condensers Reboilers Falling Film Evaporators Coolers

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | Upto 500 Sq mtr. |

| Classification : | Shell and tube - Fixed | Floating head | U-tube | Pipe in Pipe | Hair Pin Type |

| Heatexchanager for: | API , Bulkdrugs, Ethoxilation, Hydrogention, Oxidation, Distillation, Precipitation, Alkyd Resin, Polymer Emulsion Plant , Homo Polymer , Co-Polymer , Styrene Acrylic Resin, All types of resin etc |

Salient Features

- Design in compliance with international standards – ASME Sec VIII & TEMA

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines.

- Engineered to avoid unequal distribution of fluid flow.

- Close tolerance of internals enables high heat transfer coefficient & optimum operating cost

- Extensive analysis and testing of raw materials as per standards.

- Tubes sourced from most reliable manufacturers.

- Consideration of thermal expansion between shell and tube bundle is taken care during designing stage.

- Minimizing corrosion by providing anti corrosive paint on MS Part.

Seperators Recievers Bulk Storage Tanks

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | Upto 100 KL |

Salient Features

- Design in compliance with international standards – ASME Sec VIII, API 650

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines.

- Extensive analysis and testing of raw materials as per standards.

- Minimizing corrosion by providing anti corrosive paint on MS Part.

Mixers Mixing Vessels Blenders

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | Upto 50 KL |

| Classification : | Jacketed / Limpet Coiled / Internal Coiled. |

| Blender Manufactured for : | API, Bulkdrugs, Alkyd Resin, Polymer Emulsion Plant , Homo Polymer , Co-Polymer , Styrene Acrylic Resin, All types of resin etc |

Salient Features

- Design in compliance with international standards – ASME Sec VIII DIV I , DIN, PED

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines

- Energy Efficient agitator design.

- Agitator design to meet product specification to get better yield.

- Better Heat Transfer

- Statically / Dynamically balanced agitator to ensure vibration free operation

- Reduce maintenance & operating cost due to high accuracy in agitator ( maintaining permissible run out , perpendularity, concentricity of agitator ).

Crystallisers Evaporators

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | Upto 50 KL |

| Classification : | Jacketed / Limpet Coiled |

Salient Features

- Design in compliance with international standards – ASME Sec VIII DIV I , DIN, PED

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines

- Energy Efficient agitator design to crystallise and evaporate the product.

- Agitator design to meet product specification to get better yield.

- Better Heat Transfer

- Statically / Dynamically balanced agitator to ensure vibration free operation

- Reduce maintenance & operating cost due to high accuracy in agitator (maintaining permissible run out , perpendularity, concentricity of agitator ).

Distillation Units

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | Upto 50 KL |

| Classification : | High Vacuum Distillation Units | Atmospheric Distaillation Unit |

| Distillation Unit : | comprises of Distillation Kettle, Distillation column, Heat Exchanger, Separator, Receiver. |

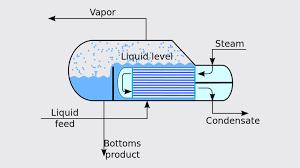

Reboiler

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | Upto 50 KL |

| Classification : | Kettle Type | Forced Circulation Type | Thermosyphon Type |

Salient Features

- Design in compliance with international standards – ASME Sec VIII DIV I , DIN, PED

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines

- Better Heat Transfer

- Reducing corrosion by providing anti corrosive paint on MS Part.

Agitators

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | Upto 50 KL |

Axial-Flow Impellers

- Pitched Blade Paddle - Cut

Blades are positioned at 45o Angle creating a recirculation pattern returning back to impeller hub. Baffles are provided to get effective flow pattern. This draws least power and has least velocity fluctuations. It has lowest micro-scale turbulence and lowest shear rate. - Pitched-Blade Turbines

Desired where high axial circulation rate is required. It is effective for rapid submerge of floating particulate solids. It draws most power and has highest micro-scale shear rate

Radial-Flow Impellers

- Curved Blade Turbine

It gives low pumping capacity and high shear rates. It is used where solids get settled in reaction. - Flat Blade Turbine

Used in Low Viscosity product. Baffles are used as Vortex Breaker.

High-Efficiency Impellers, Hydrofoil

Nowadays High Efficiency Impeller is used. It is designed to Maximize Flow And Minimize Shear Rate. Generally baffles are used with the impeller.

Close-Clearance Impellers

- Anchor Impeller:

Anchor is used where it is desired to have mixing energy concentrated out near the tank shell (usually in pseudo-plastic fluids ). It is used to obtain improved heat transfer for High Viscosity Product. - Helix / Double Helix Impeller:

It is used for product having Laminar Flow Pattern. It is closed clearance impeller. Double Helix Impeller is suitable for blending of liquids and solids from the surface. It is designed to move material up and down resulting in efficient heat transfer.Generally used where viscosity is more than 30000 cps. - MIG Stirrer

- Designed to get up and down movement to product. It draws less power.

- New Agitator Requirement/Recommendation

- Retrofitting of impeller geometry to the existing reactor for desired process results

- Optimisation of mixing based on the process requirement

- Optimisation of yield/batch time/heat transfer/mass transfer etc.

- Energy efficient impellers for power saving

- Specialised impellers for Gas Dispersion (Hydrogenation/Fermentation)

- Specialised geometry for high viscosity application (Polymerization etc.)

- Crystallization with improved crystal shapes and size

- Reactor with solid/slurry contents

Ribbon Blenders Mass Mixer Paddle Mixer

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | Upto 10 KL |

| Classification : | Jacketed / Limpet Coiled. |

Salient Features

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines

- Extensive analysis and testing of raw materials as per standards.

- Energy Efficient ribbon / Paddle design.

- Ribbon / Paddle design to meet product specification to get better mixing.

- Statically balanced to ensure vibration free operation

- Special braided gland packing in stuffing box to provide leak free operation.

- Documentations as per cGMP standards.

- Reducing corrosion by providing anti corrosive paint on MS Part.

Octogonal Double Cone V Blenders

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | Upto 5 KL |

Salient Features

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines

- Extensive analysis and testing of raw materials as per standards.

- Efficient design to ensure best mixing and easy discharge of material.

- Ensuring safety with provision of safety limit switches.

- Manual/ Electronic Inching arrangement for charging of raw material.

- Documentations as per cGMP standards.

Vacuum Nutsche Filter Pressure Nutsche Filter

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | Upto 6 KL / Filter plate dia 2500 mm dia |

| Classification : | Jacketed / Limpet Coiled. |

Salient Features

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines

- Extensive analysis and testing of raw materials as per standards.

- Documentations as per cGMP standards.

- Filter plate resting design to provide leak free operations.

- Reducing corrosion by providing anti corrosive paint on MS Part.

Sparkle Filter Zero Hold Up

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | 8 – 33" Diameter having 0.22 to 7.82 sq mtr filtration area. |

Salient Features

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines

- Extensive analysis and testing of raw materials as per standards.

- Fast and Easy Removal of Cake

- Crystal Clear filtration upto 1 micron

- Hot Filtration possible with provision of jacket.

- Skid mounted for easy handling and movement.

- Documentations as per cGMP standards

Tray Dryer

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | upto 396 trays. |

Salient Features

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines

- Extensive analysis and testing of raw materials as per standards.

- Documentations as per cGMP standards.

- One Piece fully welded chamber design crevices free to suit cleaning.

- Radiator type design increase heat transfer rate over finned type.

- Safety grid – flat type – easy cleaning

- Provision of Explosion Safety Flap

- Designed to suit uniform circulation of air, hence faster drying time.

- Door Gasket: Lip type helps proper sealing and leak free operation.

Vacuum Tray Dryer

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | upto 198 trays. |

| VTD System comprises of : | VTD, Column, Condenser, Reciever. |

Salient Features

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines

- Extensive analysis and testing of raw materials as per standards.

- Documentations as per cGMP standards.

- One Piece fully welded chamber design crevices free to suit cleaning.

- Radiator type design increase heat transfer rate over finned type.

- Safety grid – flat type – easy cleaning

- Designed to suit uniform circulation of air, hence faster drying time.

- Door Gasket: Lip type helps proper sealing and leak free operation.

Fluid Bed Dryer

| Material of Construction : | SS 316L / SS 304L / SS904 L /SS 321 / SS 316 Ti & other alloys |

| Capacity : | 30 – 250 KG/HR. |

Salient Features

- Design in compliance with cGMP standards to meet FDA & USFDA guidelines

- Extensive analysis and testing of raw materials as per standards.

- Documentations as per cGMP standards.

- Uniform drying and reduction in drying time.

- PRE/ Micro V & HEPA filter for air filtration.

- Manually operated air damper for controlling the flow of inlet and outlet air.

- Explosion Safety Flap

- Pneumatic lifting of product container & finger bag shaking with butterfly valve.

High Speed Disperser

| Material of Construction : | SS 316L / SS 304L |

| Capacity : | 1 HP to 150 HP. |

Salient Features

- Designed to manufacture medium viscosity paint, ink, adhesive, polymer and other chemicals

- Designed for dispersion of liquid – liquid, liquid – solid.

- Advantageous as same disperser can be used for more number of products by changing it with trolley tanks.

- Can be designed for vacuum application as per requirement.

- Can be designed for Flame-proof area as per requirement

- Special design of cowl to give faster & better mixing.

- Hydraulic lowering and lifting System.

- Balanced CG of Head Boom to trouble free operation resulting in higher lifespan of seal and ram.

- Safety switches for Mix-Can position, Stirring etc.

Multi Shaft Disperser

| Material of Construction : | SS 316L / SS 304L |

| Capacity : | 1 HP to 150 HP. |

| Classification : | Side by Side Type | Co-axial Type |

Salient Features

- Designed to manufacture medium & high viscosity paint, ink, adhesive, polymer and other chemicals

- Advantageous as same disperser can be used for more number of products by changing it with trolley tanks.

- Can be designed for vacuum application as per requirement.

- Can be designed for Flame-proof area as per requirement

- Special design of cowl to give faster & better mixing.

- Hydraulic lowering and lifting System.

- Balanced CG of Head Boom to trouble free operation resulting in higher lifespan of seal and ram.

- Safety switches for Mix-Can position, Stirring etc.

THREE SHAFT DISPERSER

| Material of Construction : | SS 316L / SS 304L |

| Capacity : | Custom built. |

| Classification : | Side by Side Type |

Salient Features

- Designed to manufacture medium & high viscosity paint, ink, adhesive, polymer and other chemicals

- Advantageous as same disperser can be used for more number of products by changing it with trolley tanks.

- Can be designed for vacuum application as per requirement.

- Can be designed for Flame-proof area as per requirement

- Special design of cowl to give faster & better mixing.

- Hydraulic lowering and lifting System.

- Balanced CG of Head Boom to trouble free operation resulting in higher lifespan of seal and ram.

- Safety switches for Mix-Can position, Stirring etc.

High Speed Emulsifiers

| Material of Construction : | SS 316L / SS 304L |

| Capacity : | 1 HP to 150 HP. |

Salient Features

- Designed to manufacture low to high viscosity paint, ink, adhesive, polymer and other chemicals

- Designed for dispersion of liquid – liquid, liquid – solid.

- Advantageous as same emulsifier can be used for more number of products by changing it with trolley tanks.

- Can be designed for Flame-proof area as per requirement

- Special design of cowl to give faster & better mixing.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.